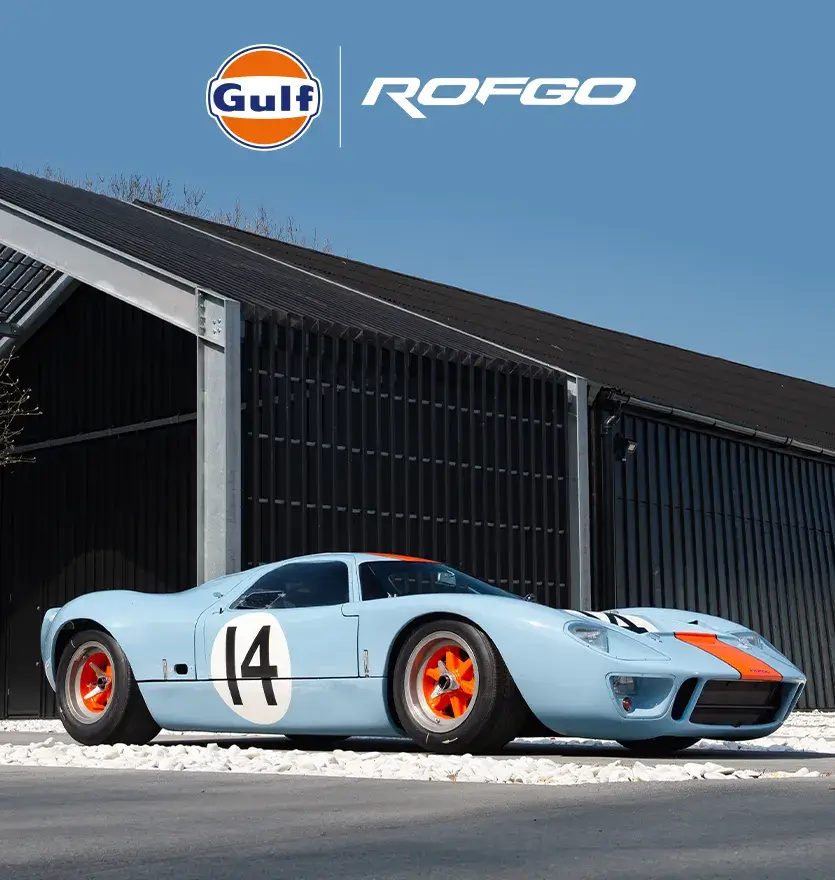

Together, We’re Unstoppable

Being one of the leading providers of fuel retail stations, lubricants and oil change services is what we do best, but at our core, we’re a brand that’s built on so much more. When we reflect on our rich history stretching back to 1901, we feel a deep sense of pride for all that we’ve achieved; the partnerships we have built, the obstacles we have overcome and the milestones we have celebrated together, as an unstoppable team.

Learn MoreAn unstoppable team

A hundred years of evolving, allowing us to serve over a hundred countries worldwide. At Gulf, we help to cater to all your needs with expert support and clever solutions to maximise efficiency day in and day out. Everything we do, from lubricants to retail fuel stations, is done with one goal in mind: driving performance at all times. We promise to stay by your side, supporting your will to succeed and your courage to keep moving forward as you pursue new and ambitious goals. The sky’s the limit and together, we’re unstoppable.

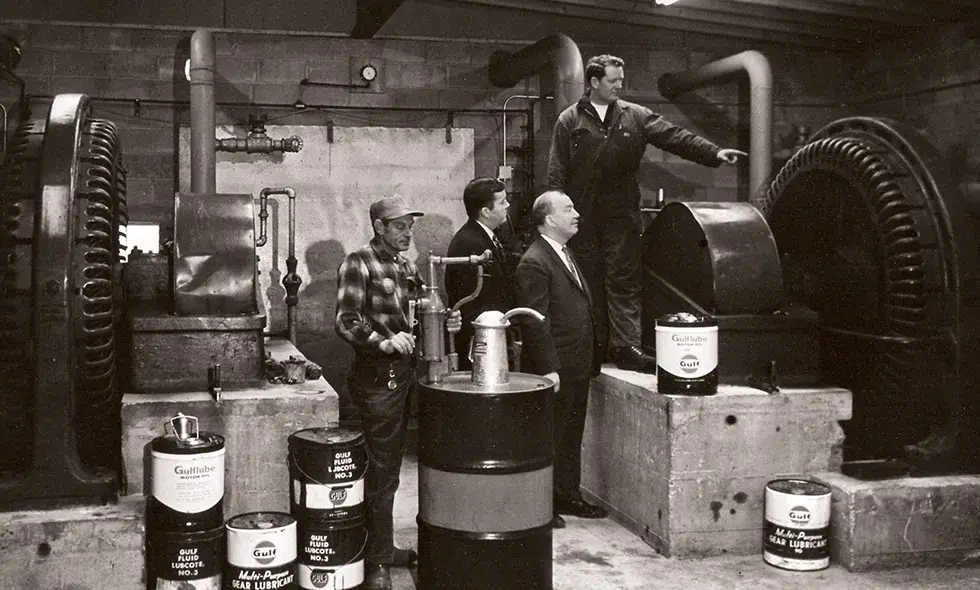

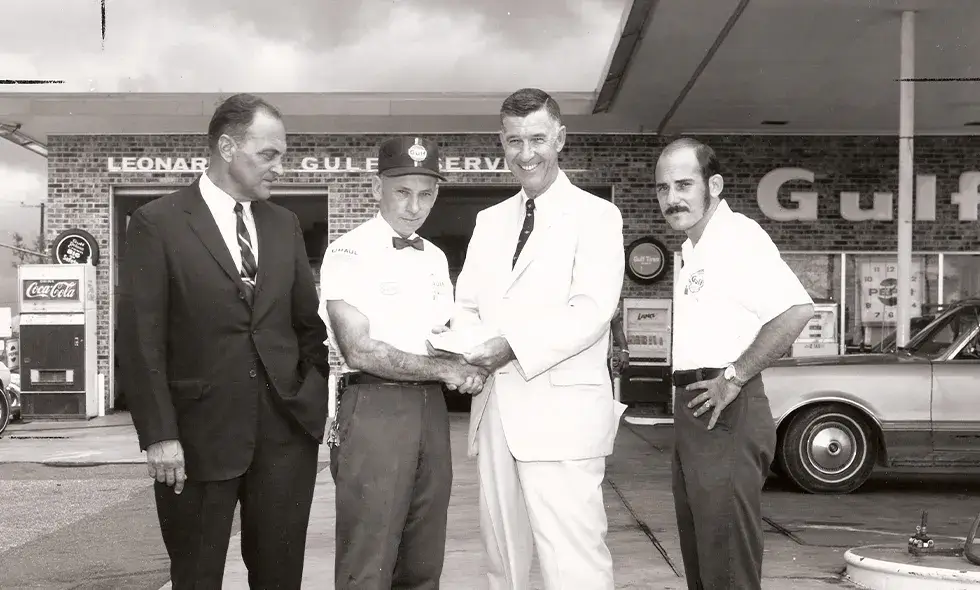

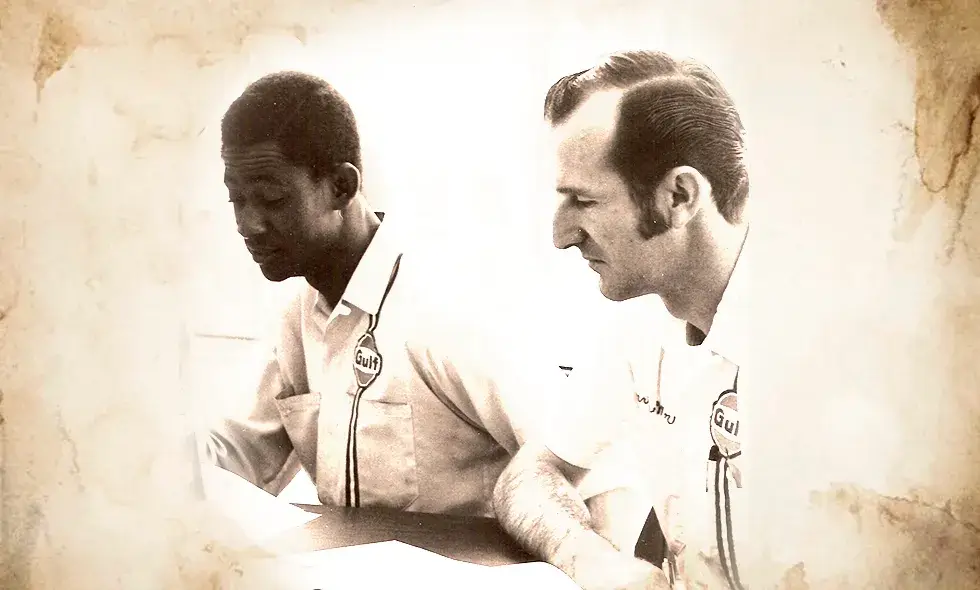

Gulf’s Heritage

Since 1901, we have been a globally recognised brand trusted by millions of people worldwide. This consistency and enduring success would not be possible without the relationships we’ve built and sustained over the years.

Discovery

Founded in Texas, selling gasoline in containers

Deep dive

Gulf launches the world’s first-ever water drilling operation

Fill it up

Gulf introduces the first drive-through fuel station

Hello Gulf!

Gulf’s orange disc logo makes its first appearance

In business

Gulf purchases the Barco oil concession

What’s New

Find out more about what’s happening at Gulf. Check out our latest news and updates...